SBR process introduction

SBR is Sequencing Batch type Activated Sludge Process (Sequencing Batch Reactor Activated

Sludge Process) acronym.It was first proposed by British scholars Ardern and Lockett in

1914, but was soon replaced by continuous activated sludge method due to the easily blocked

aerator, low level of automatic control and complex operation management.Until the 1970 s,

along with all kinds of new type aerator, floating out of the water weir (decanter)

automatic control and monitoring of hardware and software technology development, especially

the continuous improvement of the computer and industrial control technology, the sewage

treatment process for automatic operation has become possible, SBR process attracted much

attention for its unique advantages, and rapid development and application, in the world

now has hundreds of SBR sewage treatment plant in run successfully.The us national

environmental protection agency (EPA) believes that SBR process is a low investment,

low operating cost and maintenance costs, high efficiency of environmental governance

technology.

SBR is a kind of activated sludge process. Its reaction mechanism and pollutant removal mechanism are

basically the same as the traditional activated sludge process, but the operation mode is very different.It

breaks up the units of the process in chronological order, and the whole process is intermittent for a single

unit of operation.Typical SBR sets aeration and precipitation in one tank, no need to set up two sedimentation

tank and sludge reflux equipment.In this system, the reaction tank in a certain time interval is full of water,

running in batch processing way, after processing, the mixture of precipitation, with the help of a special clean

ing fluid drainage equipment out, precipitation of biological sludge are left in the pool, used for mixed with

sewage wastewater treatment again, so that, in turn, run repeatedly, constitutes the sequencing batch type

process.The typical SBR system is divided into five stages: inlet, reaction, precipitation, drainage and idling.

典型的运用SBR技术处理污水的基本运行模式如下图所示:

SBR工艺具有以下几个主要的优点:

1. 处理构筑物很少,一个SBR反应器集曝气、沉淀于一体,省去了初沉池、二沉池和回流污泥泵房。因此,大大节约了处理构筑物的占地面积、构筑物间的连接管道及流体输送设备,一般可降低工程总投资的10%~20%。

2. 由于其间歇进水,时间长短、水量多少均可调节,因此对水量水质的变化具有较强的适应性,不需另设调节池。

3. 占地少,比传统活性污泥法少占地30%-50%,是目前各种污水处理工艺中占地最省的工艺之一。

4. 可脱氮除磷。通过调节曝气时间和间歇时间,使污水在反应池中处于交替好氧、缺氧和厌氧状态,为工艺脱氮除磷创造了条件。同时,这种环境条件的变化也可以有效抑制丝状菌的生长,减少污泥膨胀的影响。

5. 污水处理厂刚建成运行时,流量一般比设计值低,SBR可以根据水量水质的需要,增减运行池体的数量,这样可以避免不必要的能量消耗,这是其他工艺所不具备的。

SBR工艺的主要缺点有:

1. 反应池的进水、曝气、排水过程变化频繁,不能采用人工管理,因此对污水厂设备仪表的要求较高,并要求管理人员有一定的技术水平。

2. 水量较大时会暴露出容积利用率不高的问题。

1.2 SBR改良工艺介绍及对比

SBR运行方式灵活多变,适应性强,为满足不同的水质及实际工程的要求,可对工艺过程进行改进,随着基础研究方面的不断进展以及人们对活性污泥去除污染物质机理的逐渐了解,鉴于经典的

SBR技术在实际工程应用的一定局限,为适应实际工程的需要,SBR技术逐渐衍生了各种新的形式。

目前应用较多的改良工艺有:ICEAS,UNITANK,DAT-IAT,CAST(CASS)等。

1.2.1 ICEAS工艺原理

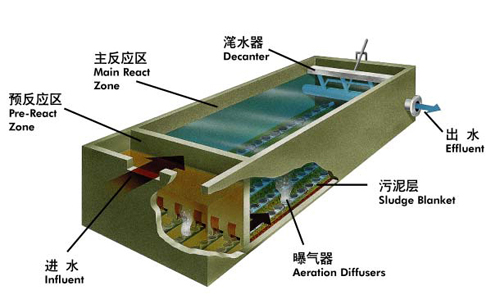

ICEAS全称为间歇式循环延时曝气活性污泥法(Intermittent Cycle Extended Aeration),其最大的特点就是在反应器的进水端增加了一个预反应区,运行方式为连续进水(沉淀期、排水期仍连续进水),间歇排水,无明显的反应阶段和闲置阶段。污水从预反应区以很低的流速进入主反应区,对主反应区的泥水分离不会产生明显影响。由于ICEAS设施简单、管理方便,尤其是处理市政污水和工业废水方面比经典的SBR系统费用更省,因此在国内外受到了广泛重视。自20世纪80年代初在澳大利亚兴起以来,目前已建成投产了300多座污水处理厂。

ICEAS的运行方式如图1-2所示:

将SBR反应池沿长度方向分为两个部分,前部为预反应区,后部为主反应区。预反应区可起调节水流的作用,主反应区是曝气、沉淀的主体。ICEAS是连续进水工艺,不但在反应阶段进水,在沉淀和滗水阶段也进水。污水进入预反应区后,通过隔墙底部的连接口以平流流态进入主反应池,在主反应池中进行间歇曝气和沉淀滗水,成为连续进水、间歇出水的SBR反应池,使配水大大简化,运行也更加灵活。

ICEAS工艺中各操作单元的作用为:

A、曝气阶段 由曝气系统向反应池内间歇供氧,此时有机物经微生物作用被生物氧化,同时污水中的氨氮经微生物硝化反硝化作用,达到脱氮的效果。

B、沉淀阶段 此时停止向反应池内供氧,活性污泥在静止状态下降,实现泥水分离。

C、滗水阶段 在污泥沉淀到一定深度后,滗水器系统开始工作,排出反应池内上清液。在滗水过程中,由于污泥沉降于池底,浓度较大,可根据需要启动污泥泵将剩余污泥排至污泥池中,以保持反应器内一定的活性污泥浓度。滗水结束后,又进入下一个新的周期,开始曝气,周而复始,完成对污水的处理。